Your cart is currently empty!

About

Murdock Fountain Restoration Project

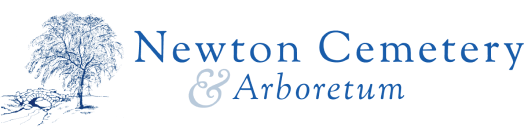

The Murdock Fountain in Newton Cemetery is located just beyond the main gate and across the road from the office in a wide expanse of lawn dotted with trees and shrubs. It prominently greets visitors as they enter the cemetery and provides a soothing location for reflection as the water splashes from the two upper bowls to the lower basin.

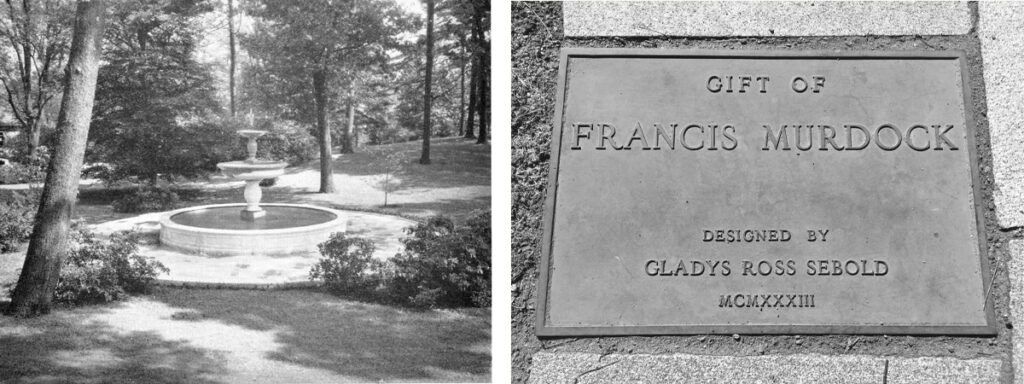

The fountain is named for Francis Murdock, who was the nephew of the Corporation’s first treasurer, Joseph N. Bacon. He was a trustee of the Newton Savings Bank, the Newton Trust Company and the Newton National Bank and served the Newton Cemetery Corporation for over forty years as clerk, auditor and trustee. When he died in 1917, he left $5,000 for a fountain to be erected in his memory. Because of the “high cost of materials” it was decided to invest the money and allow interest to accumulate until there were sufficient funds for a memorial “worthy of the giver”.

“While investigating the fountain prior to the restoration, it became apparent that the capability of granite fabrication of fountains of this scale has been drastically reduced over the years and has, in many ways, become a lost art form. While discussing the main fountain bowl itself, many of the quarrymen and fabricators I showed it to state that in all likelihood pieces of this size would have to be rendered in CAD and sent off to China for production. I find it sad to know that the skilled hands that originally created the fountain have no regular representation within our society like they did back then. To me, it only increases the historical significance of pieces of work such as this.”

– Jay Bearfield, Liquid Landscape Designs

The subject was discussed several times in the years that followed, but it was not until 1933 that the Trustees approved the fountain design by Gladys (Ross) Sebold, daughter of the first cemetery superintendent Henry Ross. Mrs. Sebold was a member of the Newton High School class of 1919 and the Smith College class of 1924. After receiving her A.B. from Smith, she entered the Cambridge School of Architecture & Landscape Architecture where she took courses and did field work from 1924 to 1927. In June 1927, she received a Certificate in Landscape from the Cambridge School. In 1934, when the Cambridge School and Smith College affiliated, her Certificate was re-evaluated and she received a Master’s in Landscape Architecture at the June 18th Commencement ceremony. She worked for three years in the New York City office of Beatrix Farrand, one of the founding members, and the only woman, of the American Society of Landscape Architects. Both Mrs. Ross and her husband (a professor of landscape architecture) were members of the ASLA.

The contract for construction was awarded to Jones Brothers Co., a locally-owned quarry business that also provided the granite for the fountain. The owner, Seward W. Jones, was a Newton resident and was active in the Massachusetts legislature. When he died, he was interred at Newton Cemetery in a family lot located near the fountain. The fountain project included laying a thousand feet of pipe to carry water to and from the Chapel ponds, and, as in the case of the new City Hall then under construction across Homer Street, gave “employment to quite a force of men” at a time when work was hard to find.

After many decades, Murdock Fountain was in need of attention. The large granite stones forming the lower basin of the fountain had settled, opening joints between the stones as well as creating a large gap between the basin and the stones, allowing water to penetrate between the granite outer pieces and the bowl. The freezing and thawing of the water between the bowl and granite exacerbated the deterioration of walls of the lower fountain and bowl. The basin stones were in danger of falling apart and were temporarily held in place by a large strap secured by a ratcheting buckle.

In May 2013, the existing conditions were discussed at the Annual Meeting of the Newton Cemetery Board of Trustees. The Board spoke about the history and significance of the fountain and noted its prominence at the front entrance. The importance of cemetery maintenance and preservation was agreed upon and in a motion duly seconded, it was voted to proceed with the fountain restoration.

Structures North Consulting Engineers (the same firm that designed the repairs to The Civil War Memorial owned by the City of Newton, also located in Newton Cemetery) was retained as the restoration consultant. The first phase of their services involved an investigation and study of the existing fountain and its foundation. Cemetery staff carefully excavated areas as directed by the engineers to expose the foundation conditions. Structures North then examined the structure of the fountain and its foundation. It was astounding to realize that the fountain had no real footings, minimal concrete reinforcement and was positioned on unstable ground centered within a depression- all contributing factors to the failure of the fountain. It was amazing that the fountain stood as long as it did!

Once the investigation was complete, Structures North prepared design documents reflecting the findings and detailing the appropriate methods of repair. It was determined that in order to properly restore the fountain and the underlying structure, the fountain needed to be carefully dismantled, the existing inadequate foundation removed, a new foundation built and the dismantled pieces carefully reconstructed.

Before the fountain repairs commenced in the spring of 2014, Newton Cemetery grounds staff removed the surrounding overgrown vegetation to allow access to the area. This included removal of shrubs to the left of the front gate which were not in the immediate fountain area, but were overgrown and obscured views to the fountain upon entering the cemetery. Once this was done, Schumacher Landscaping and Liquid Landscape Designs worked together to carefully dismantle and re-build the fountain. Meticulous review of each piece both prior and during disassembly was paramount to ensure the structural stability of each piece. Every fountain piece was examined, cataloged and mapped before dismantling began. The existing mechanical, electrical and plumbing components were removed first. Then, each unique, hand-cut granite paver was documented and labeled before being removed and stored on site. The entire fountain was shored up prior to dismantling the pieces. A crane was utilized to remove the two upper granite bowls and granite pieces surrounding the lower basin of the fountain. The fountain bowls, surround pieces and pavers were all stored on site in close proximity to the fountain in order to minimize potential damage. After the granite fountain pieces and pavers were carefully removed, the existing concrete footings and interior of the lower fountain bowl were demolished.

The site was then prepared for a new foundation and the formwork, rebar, footings and walls were put in place. The foundation was back-filled and piping from the pump to the fountain installed.

The cataloging and mapping of each piece was crucial to the rebuilding process, allowing for a smooth reinstallation. The granite surround pieces were carefully installed and anchored on the new foundation before work began on the lower bowl. By utilizing gunite, a type of concrete shot into place over rebar to reduce additional air trapped within the mix, the new bowl was more structurally sound than the original bowl, which had utilized a mix and pour method. Additionally, a foam barrier was placed between the granite coping (top of the granite surround pieces) and the gunite water bowl to reduce the likelihood of any future issues should a piece need to be repaired. The foam barrier prevented the bowl from locking into the granite itself, which would make it very difficult to separate the pieces from the shell. In addition, an epoxy coating was installed on the cured concrete shell, further protecting the concrete from moisture penetration and maintaining its integrity.

After the gunite had been installed and cured, the fountain bowls were placed back into position, pinned together and fit with new plumbing and nozzles. The team from Liquid Landscapes had many conversations on site about the sheer size of the fountain and the limited machinery available to the original installation crew. They were baffled by how the installation must have been done, but thankful for the technology available now to handle such pieces with ease and care. Modern equipment allowed for disassembly practices that put the least amount stress on each piece of the fountain. A new underground pump vault box, pump and filter were installed in the same location as the original, above-ground equipment previously removed. The existing granite pavers were re-installed per their original layout in a sand bed on top of a concrete slab. Reinstallation of the pavers was akin to putting a puzzle together as all the pieces were unique in shape, size and thickness, and fit together in a certain way. The Murdock Fountain Restoration was completed in the fall of 2014 with the sod installation as the finishing touch.

The restoration of the Murdock Fountain ensures the landmark will last for many generations of visitors to appreciate and represents the importance placed on preservation and maintenance at Newton Cemetery.